Features

l Applicable to prefilled syringes of various brands, other types of syringes can also be customized.

l The surface is made of SUS304 stainless steel, and the parts in contact with materials are made of SUS316L stainless steel and medical grade silicone rubber, which meets the requirements of GMP regulations.

l Ceramic plunger pump realizes quantitative filling, acid and alkali corrosion resistance, wear resistance and high temperature resistance, and high filling accuracy.

l The sorting and conveying of the rubber stoppers is realized by the vibrating plate, which adopts SUS316L stainless steel clean plate, without cleaning dead angle, and the top plate is detachable and supports sterilization.

l Adopt international famous brand electrical components, implement non-interference modular control, all synchronous actions are controlled by servo motors, accurate and reliable, and easy to operate.

l The operation of the motor is controlled by the PLC programming controller, the human-computer interaction interface monitors and displays the working status of each station in real time, and the real-time automatic alarm displays the fault location and fault prompt.

l A variety of filling doses and filling methods are available, supporting the storage of various formula parameters.

l The injection needle is used to fill with the liquid level rising to prevent the liquid medicine from splashing.

l Vacuum filling system, suitable for high-viscosity materials, ensures that the liquid medicine fills the filling space without bubbles or faults, and improves the qualified rate of finished products.

l Vacuum plugging system ensures that the rubber stopper is in close contact with the liquid surface when filling high-viscosity materials.

l It can be used for prefilled syringes of various specifications by changing the specifications. It is modularized and easy to expand. It can be used as a stand-alone machine or connected to a denesting machine, rotary rod machine, labeling machine, light inspection machine and other equipment to form a production line.

l Optional rubber stopper self-cleaning station can be added without stopping the machine.

l Class A laminar flow hood is optional to achieve high-demand clean production.

Main Technical Parameters

Applicable Materials

Liquid and ointment

Applicable Specifications

1ml long/1-3ml/5ml/10ml

(Need to replace specifications)

Filling Range

0.1-10ml

(Need to replace plunger pump)

Number of Injection Nozzles

1

Filling Accuracy

≤±1.5%

Production Capacity

600-800 pcs/h

Power

2.5kw

Voltage

380V 50Hz

Compressed Air

0.6-0.7Mpa

Dimensions

L808×W758×H1760mm

Weight

380kg

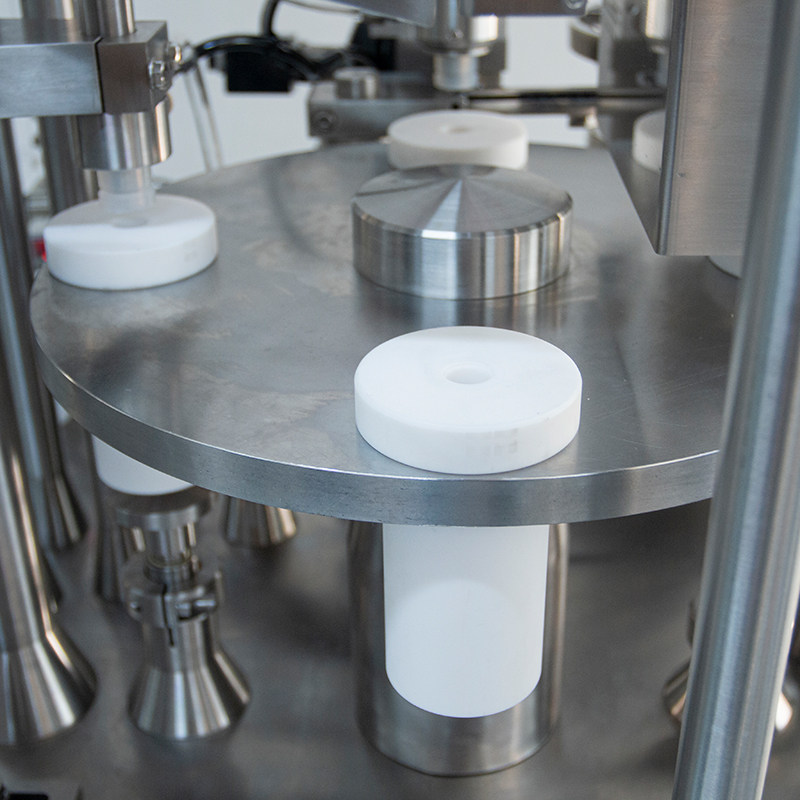

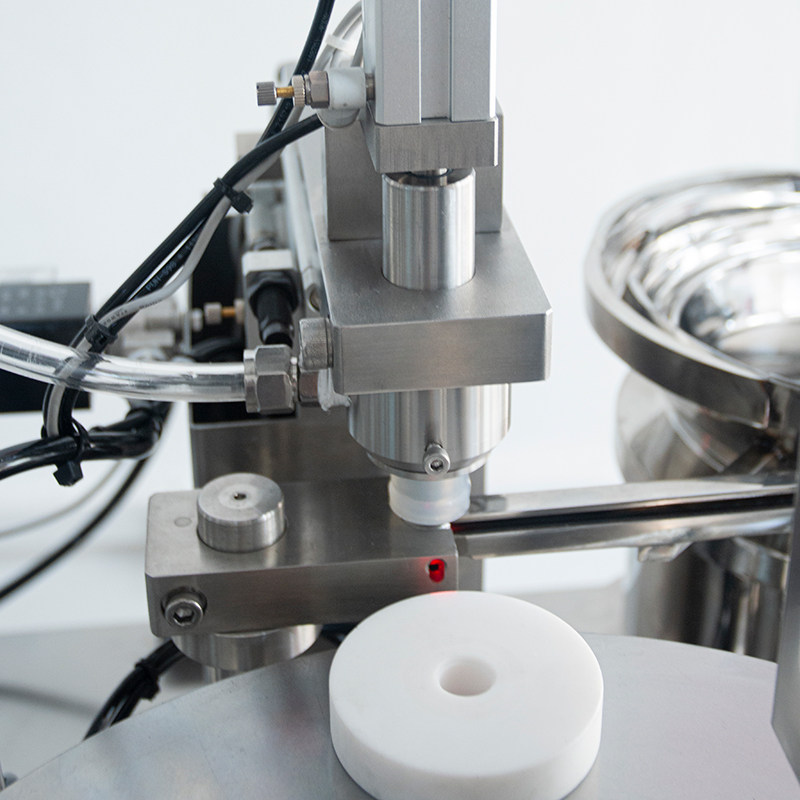

Product Details 1

Product Details 2

Product Details 3

Product Details 4

Applicable packaging materials

Equipment drawings