Product Features

The body is made of 304 stainless steel, with excellent workmanship and in compliance with GMP specifications.

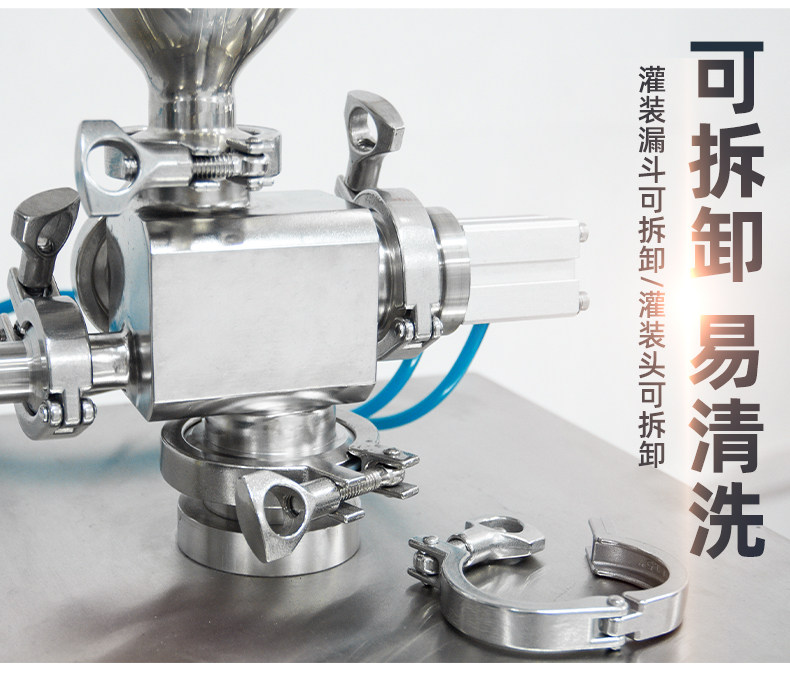

The machine has a reasonable structural design and is equipped with stainless steel quick release connectors, making disassembly and assembly fast and convenient, and easy to clean and maintain.

The pure pneumatic filling method is adopted, requiring no electricity. It is particularly suitable for use in explosion-proof and humid environments, with high safety.

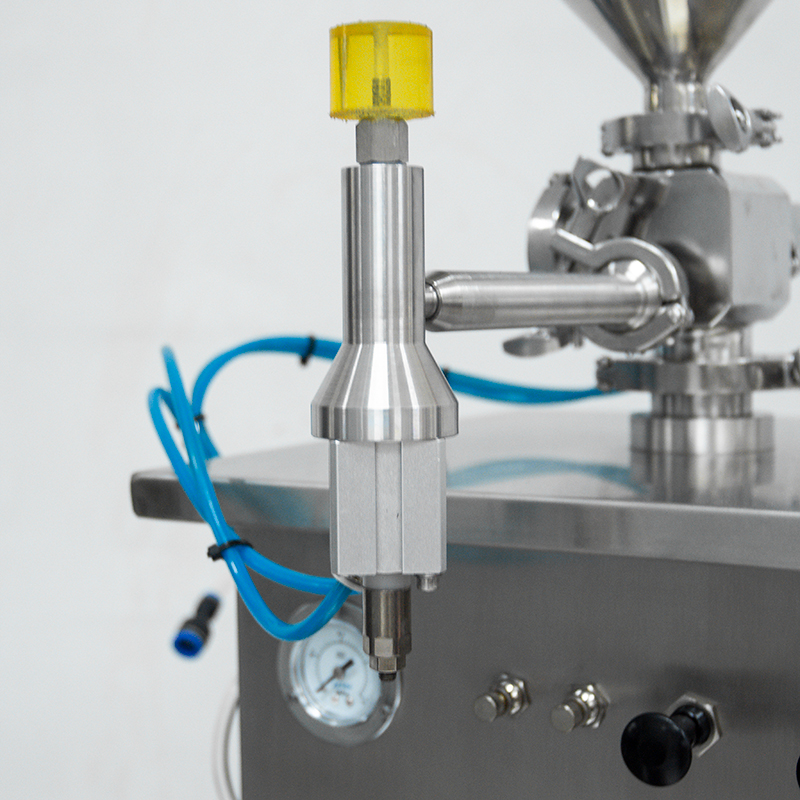

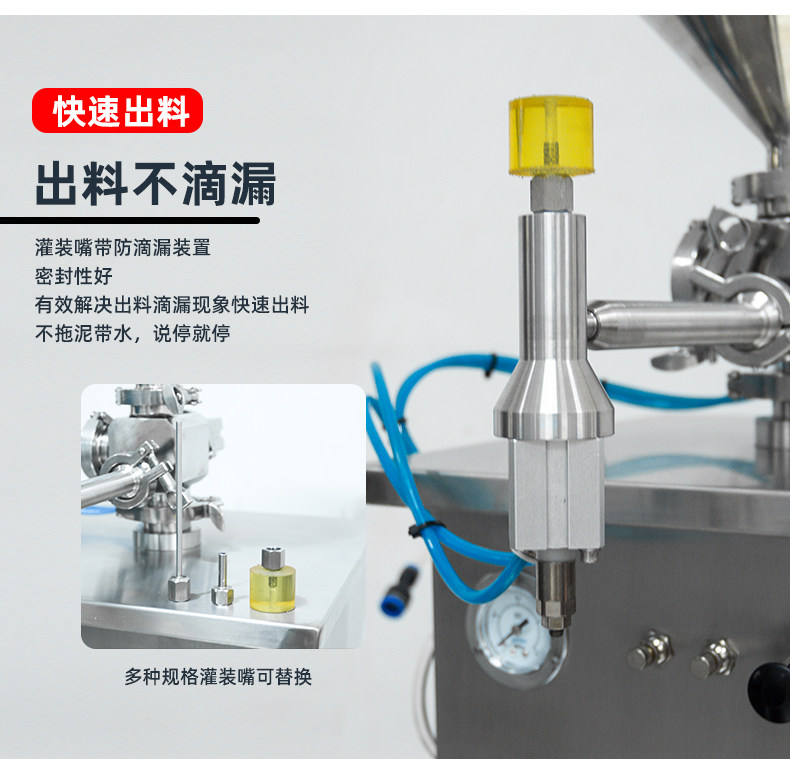

The material outlet adopts a drip proof filling nozzle with good sealing performance to ensure accurate filling.

The caliber of the crystal head of the filling nozzle can be customized according to the diameter of the needle head, which is suitable for various specifications of syringes.

The new upgrade adopts a five-way rotary valve, which can choose to use a hopper for feeding or use a feed pipe for feeding, suitable for a variety of materials.

Using internationally renowned pneumatic components, it is stable and durable, ensuring the reliability of the machine.

The control panel is equipped with a barometer to monitor the air pressure at any time, and the discharge and suction speeds can be adjusted.

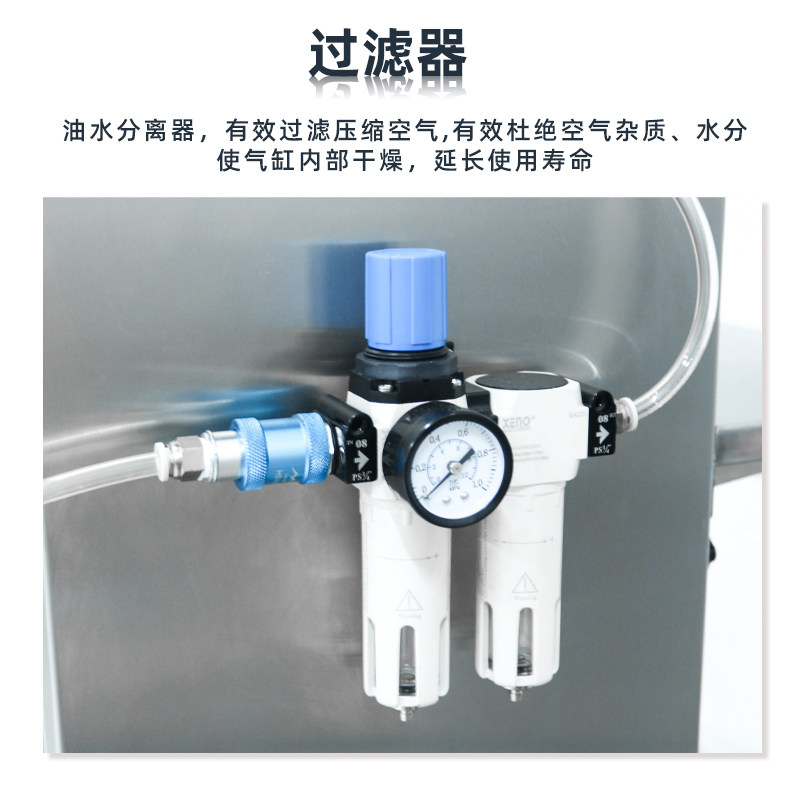

An oil water separator is installed on the left side of the machine body, effectively filtering compressed air, drying the inside of the cylinder, and providing a long service life.

Manually adjust the filling amount, easy to operate, and easy to use.

Height adjustable console with excellent load carrying capacity, suitable for a variety of products.

The foot switch is convenient and flexible to use, and the manual/automatic feeding methods can be freely switched.

Product Details 1

Product Details 2

Product Details 3

Product Details 4

Applicable packaging materials

Main technical parameters

Applicable materials

Water and paste

Filling range

1-50ml

Filling Precision

≤±2%

Filling speed

10-30 times/minute

Working air pressure

0.4-0.8Mpa

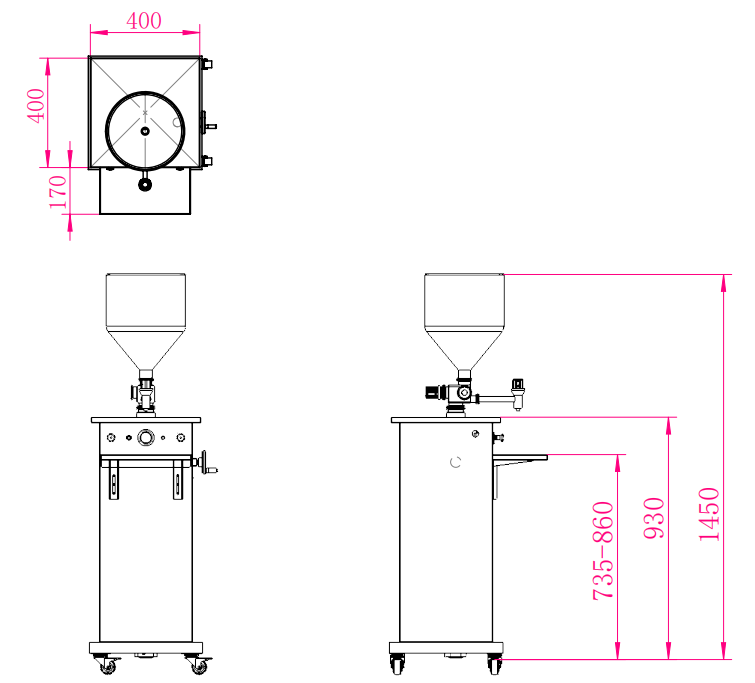

Overall dimensions

L400×W400×H1500mm

Operating Weight

60KG

Equipment drawings